Hardcore strength casts high-end quality, Changan Qiyuan E07 is the most preferred 300,000 strength

In 2024, Changan Automobile joined hands with industry giants such as Huawei and China Unicom to bring together the top digital transformation strategies and technical essence in the industry, and proudly built a 5G intelligent AI flexible super factory covering the whole area in Yubei District, Chongqing, that is, Changan Automobile Smart Factory, which aims to establish a "new model" in the field of intelligent manufacturing and showcase the cutting-edge achievements of intelligent exploration.

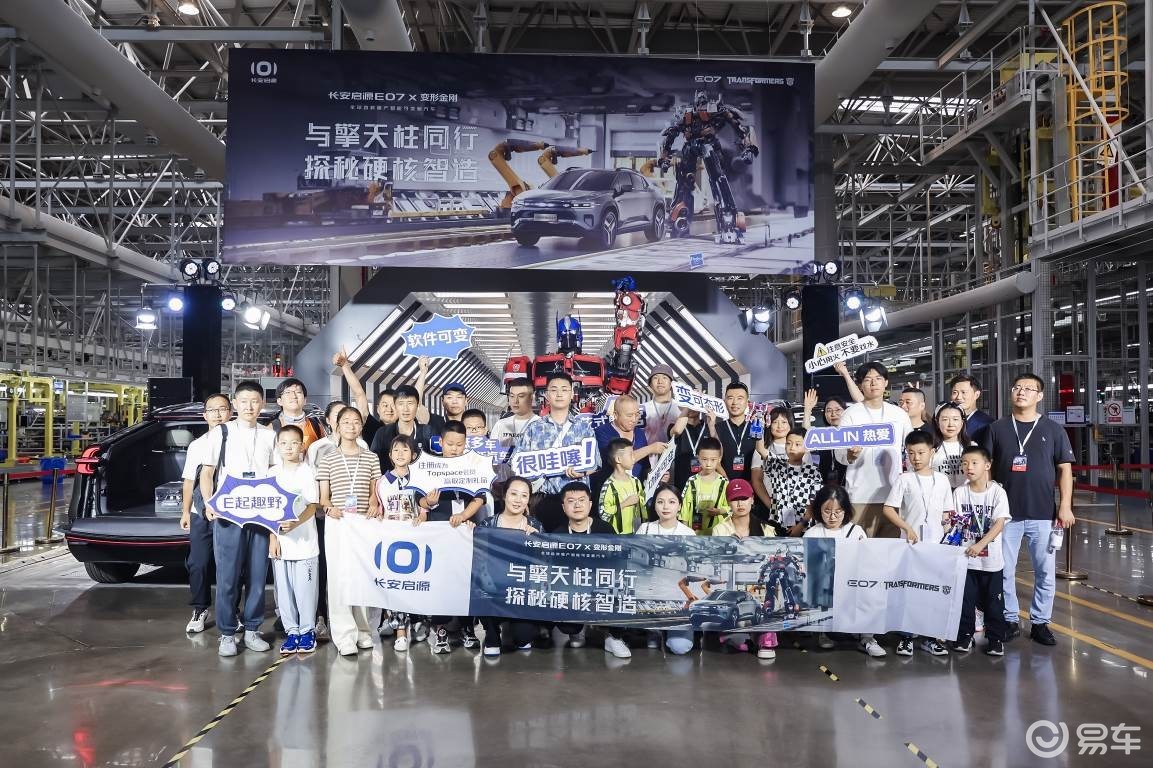

On the afternoon of July 19, the world’s first intelligent shape variable replacement model based on the SDA architecture (one car to many cars, travel to "SUV form", commute to "coupe form", load to "pickup truck form"), joined hands with the classic movie character Transformers in Changan Automotive Smart Factory. Through the live broadcast, Transformers and Changan Automotive engineers walked side by side, leading the audience to visit the six core areas of the final assembly workshop, painting line, welding area, stamping workshop, die casting center and battery manufacturing workshop, uncovering the mystery of the solid technology behind intelligent manufacturing layer by layer, and jointly witnessing and exploring the strong core competitiveness contained in Chinese manufacturing.

Future automotive intelligent manufacturing new highlands, exploring the six workshops of Changan Automobile Digital Intelligence Factory

The reason why Changan Automobile Numerical Intelligence Factory was given the exclusive mission of producing high-end Numerical Intelligence vehicles is not only due to Changan Automobile’s profound car-making heritage and experience accumulated over the past 40 years, but also its firm investment and unremitting innovation in the field of intelligent manufacturing, as well as its comprehensive embrace and deep integration of cutting-edge technology. This series of efforts have jointly built Changan Numerical Intelligence Factory’s unique advantages and core competitiveness in the field of high-end Numerical Intelligence automobile production.

In the initial chapter of automobile manufacturing, the stamping workshop played a crucial role. At present, the stamping workshop of Changan Shuizhi Factory stands out for its excellent level of automation. Its stamping production line has been fully automated. As a pioneer of Changan Automobile’s own brand, it is not only the first production line capable of controlling steel and aluminum mixed materials, but also shows extraordinary flexibility to easily cope with the production challenges of various materials such as steel and aluminum plates.

In order to ensure the excellent quality of stamped parts, the workshop introduced an innovative "online AI quality inspection + offline quality inspection" dual inspection system at the end of the stamping process. This system relies on advanced AI quality inspection algorithms deployed in the cloud, combined with industrial cameras trained by precision machine vision, to achieve all-round quality inspection and information recording of products in just one second, which greatly improves the inspection efficiency. At the same time, the application of edge algorithms is even more icing on the cake. It monitors hundreds of key quality control points in real time, ensuring the accuracy and timeliness of inspection, jointly promoting the automation process of the quality inspection process, and significantly improving the accuracy of quality inspection results.

After a comprehensive upgrade, the level of automation in the welding workshop has jumped to an unprecedented level, with more than 95% of the operation process being automated. In the workshop, 185 precision welding stations and 471 high-efficiency automated robots are distributed in an orderly manner. They work together, which not only significantly improves the precision of welding operations, but also further enhances the robustness of the body structure through the extensive use of innovative aluminum alloy riveting processes.

In particular, it is worth mentioning that in the pursuit of the ultimate strength of the body’s sidewall, the stamping workshop has adopted the industry’s leading integrated thermoforming technology, which has enabled the strength of the sidewall inner panel to achieve a qualitative leap. Compared with the ordinary car sidewall inner panel, its strength has been increased by 2-3 times.

It is the deep integration and application of this series of cutting-edge technologies that together create a new generation of safety body of Changan Qiyuan E07. This body makes a bold breakthrough in design, with the use of high-strength steel and aluminum alloys reaching more than 90%. Even key parts such as the car body and the front cover are made of all-aluminum alloy. This design is not only comparable to Tesla’s all-aluminum body design, but also has achieved remarkable results in vehicle lightweight, effectively reducing the weight of the vehicle, thereby improving fuel economy and handling performance. At the same time, the durability and safety of the body have also achieved a qualitative leap, providing drivers and passengers with a more solid and reliable safety guarantee.

Changan Shuizhi Factory leads the industry trend and takes the lead in establishing a unique fully automated flexible and unmanned die casting production workshop in China. The workshop integrates five core processes of melting, die casting, post-processing, machining and assembly, and is equipped with four top-class die casting machines weighing 7,700 tons. As a masterpiece of the factory, Changan Qiyuan E07 adopts the industry’s leading front and rear integrated die casting technology. This innovative process delicately integrates 163 components into two core parts. The die casting process takes only an astonishing 110 seconds, demonstrating unprecedented efficiency and integration capabilities.

It is particularly worth mentioning that Changan Shuizhi Factory has also pioneered a new die-casting process of "one mold and two pieces", which allows the flexible design of bumper parts and integrated die-casting parts, and achieves slow connection through ingenious mechanical structure. This design ingenuity ensures that the vehicle can effectively protect the integrated casting from damage in the event of a conventional collision, thereby greatly reducing the maintenance cost after the collision.

The in-depth application of integrated die-casting technology not only allows Changan Qiyuan E07 to achieve a significant reduction in vehicle weight, but also has a lighter curb weight of more than 100 kilograms compared to Model X. This lightweight achievement gives the vehicle more agile handling performance and positive response speed. At the same time, the torsional stiffness and bending stiffness of the vehicle have also been significantly improved by 24% and 23% respectively, and the collision energy absorption efficiency has jumped by 54%. These outstanding performances together ensure that Changan Qiyuan E07 can easily meet the stringent requirements of the upcoming 2024 version of the C-NCAP five-star safety standard, bringing users an unprecedented safe driving experience.

The painting workshop of Changan Shuizhi Factory, as an art palace of automobile beauty and protection, has introduced the first water-based environmentally friendly 3C2B process coating line in China through its innovation, which is undoubtedly another milestone in the green transformation of the automotive industry. This technological innovation has not only deeply improved the quality boundary of products, but also set a new benchmark in the field of environmental protection. Through the unique "three sprays and two dryers" process, compared with the simple "three coats and one bake" of the traditional 3C1B model, the pass rate of painting has achieved a qualitative leap, and the key performance indicators of car paints – adhesion, corrosion resistance, film hardness and durability – have been enhanced as never before, ensuring that vehicles can still show a lasting and gorgeous luster in extreme environments.

It is particularly worth mentioning that Changan Shuizhi Factory’s persistent pursuit of environmentally friendly materials. The water-based coatings used have greatly reduced environmental pollution due to their low VOC (volatile organic compound) emissions, and actively responded to the global call for low-carbon environmental protection. This gentle treatment of nature is a manifestation of Changan Automobile’s sense of responsibility as an industry leader.

In addition, the gluing ISS robot and LASD robot configured in the painting workshop are the bright pearls of intelligent production. With its micron-level accuracy, the ISS extrusion robot has completely bid farewell to the possible flaws in the era of manual extrusion, ensuring the flawless gluing process. The liquid damping glue used by the LASD robot has shown extraordinary strength in sound insulation and heat insulation, creating a quiet and comfortable private space for passengers, making every trip a pleasant journey of body and mind.

Changan Qiyuan E07, as the master of this series of advanced craftsmanship, satisfies consumers’ pursuit of personalization with its colorful 7 body colors. At the scene, the first-time users witnessed the extraordinary charm of the latest off-line matte car paint vehicles. The unique texture and luster instantly ignited their enthusiasm, and they were deeply attracted by this masterpiece that combines technology and aesthetics.

The "Golden Bell Jar Battery" carried by Changan Qiyuan E07, its birthplace – the battery workshop, is undoubtedly a bright pearl in Changan Shuizhi Factory. Here, not only the top fully automated battery packaging production lines in China are gathered, but also the industry-leading laser welding technology. The four core process links – assembly, gluing, welding and testing – are seamlessly connected here, and together they create the extraordinary quality of "Golden Bell Jar Battery".

The introduction of 235 sets of state-of-the-art equipment has enabled the pre-assembly section of the battery workshop to achieve 100% automated production. This feat not only highlights the strong strength of Changan Digital Intelligence Factory, but also makes it a model of black light factory in Asia. Here, technology and efficiency go hand in hand, precision and intelligence dance together, laying a solid foundation for the birth of "Golden Bell Battery".

The name of the "Golden Bell Battery" is due to its use of military-grade basalt nano-thermal insulation material. This high-tech material is like putting an indestructible layer of armor on the battery, achieving 100% heat suppression effect, ensuring that the battery pack can remain calm in extreme situations, without smoke, fire, or explosion, providing a solid guarantee for the user’s safe travel.

At the same time, the application of CTV integrated integration technology perfectly integrates the battery with the chassis, which not only improves the overall strength of the body and the safety of the battery, but also provides more possibilities for the design of the interior space. This innovative design allows Changan Qiyuan E07 to have excellent safety performance while also taking into account the spaciousness and comfort of the space.

The addition of 800V high-voltage fast charging technology has made the Changan Qiyuan E07’s battery life and charging efficiency reach a new height. It only takes about 15 minutes to add about 365 kilometers of cruising range to the vehicle, so that users no longer need to worry about power for every trip.

Changan Digital Intelligence Factory, as the cradle of "Golden Bell Battery", provides the most solid backing for the super safety and long battery life of Changan Qiyuan E07 with its excellent technical strength and innovation ability. Here, the birth of every battery is condensed with the crystallization of wisdom and sweat, and every effort is designed to bring users a safer, more convenient and more pleasant travel experience.

Changan Qiyuan E07, as an electric vehicle that combines technology, luxury and intelligence, every step from painting to final assembly is full of expectations and ingenuity for the future. Through the sky corridor that connects painting and final assembly, it seems to have crossed the boundaries of time and space, from a cold metal shell to an intelligent car with soul and flesh.

In the final assembly workshop, the production lines of modernization and digital intelligence complement each other, demonstrating the rapid development of China’s automobile manufacturing industry. The birth of a new digital intelligence car every minute is not only a symbol of China’s speed, but also a solid step forward for China’s automobile industry to move towards intelligence and high-end. Here, Changan Qiyuan E07 realizes the world’s leading central ring network architecture through the integration of cutting-edge technologies such as agile sensing, integrated control and super computing power, providing higher safety redundancy for vehicle control, making every trip more worry-free.

When it comes to the interior, Changan Qiyuan E07 is the ultimate interpretation of delicacy and elegance. The first-class zero-gravity seats of the main and co-pilot are equipped with functions such as electric adjustment, memory, ventilation, heating, massage, etc., bringing an unprecedented comfortable experience to the driver and occupant. The perfect combination of the space handle steering wheel and the 15.4-inch sunflower screen not only enhances the convenience of driving, but also makes the interior space full of technology and futurism. In addition, the 16:9 ratio of the co-pilot’s sun visor exclusive entertainment large screen, 18 stereo surround speakers, and the rear car 3D-PAD configuration make the interior space a mobile living space that integrates entertainment and office.

In terms of intelligent driving, Changan Qiyuan E07 has also shown great strength. Through the precise cooperation of 11 cameras, 5 millimeter-wave radars, 12 ultrasonic radars and 2 lidars as standard, it has achieved far more intelligent driving capabilities than Model X. Whether it is lane keeping assistance, parallel line assistance or lane centering function, it performs better. At the same time, its strong perception ability and real-time road topology generation ability make it possible to avoid and bypass obstacles intelligently. And the ability to automatically process 1600 kilometers of data for model training every day makes it a leading position in the new energy industry.

In terms of software, Changan Qiyuan E07 is also not to be underestimated. The world’s only central ring network architecture jointly owned by it and Cybertruck not only enhances the safety redundancy of vehicle control, but also shows the profound heritage of Chinese auto brands in integrated domain control technology. If Tesla is a pioneer in integrated domain control technology among global automakers, then Changan Qiyuan E07 is undoubtedly the leader among domestic brands. Its appearance not only allows us to see the innovation and strength of China’s auto industry, but also makes us full of unlimited expectations and vision for the future.

In addition to visiting the factory, Changan Qiyuan E07’s driving review activity also brought an unprecedented driving feast for first-time users. This model has demonstrated excellent performance and leading technical strength in terms of power, control, comfort and intelligent driver assistance systems.

In terms of power, Changan Qiyuan E07 is equipped with a system with a peak power of up to 440kW and a peak torque of 645Nm. This powerful power configuration makes its 100-kilometer acceleration capacity reach an amazing 4-second level, which is completely comparable to high-end electric models such as Model X. This acceleration performance not only makes the driver feel the ultimate sense of push, but also shows Changan’s deep accumulation in electric vehicle power technology.

In terms of handling, Changan Qiyuan E07 also performs well. Its air suspension system can realize adjustable height of 90mm and soft and hard stepless adjustment, which can be intelligently adjusted according to road conditions and driver’s needs, ensuring that the vehicle can maintain the best handling and comfort in various complex road conditions. In addition, the combination of all-aluminum alloy chassis, double fork arm front overhang and R-EPS steering system brings a delicate steering feel and stable cornering posture to the vehicle, allowing the driver to easily cope with various cornering challenges.

In terms of comfort, the Changan Qiyuan E07 also did not disappoint. The whole car uses double-layer sound insulation glass and a large number of silent materials, which effectively isolates most of the wind noise and road noise, creating a quiet and comfortable riding environment for the driver. This sense of tranquility is even comparable to that of a million-class luxury car, allowing the driver to enjoy the comfortable experience of being in a luxury cockpit while enjoying high-speed driving.

Finally, the Changan Qiyuan E07 is also equipped with the high-level intelligent driving assistance system independently developed by Changan Automobile. This system not only has the function of automatically identifying parking spaces and selecting empty parking spaces by itself, but also provides more advanced intelligent driving auxiliary features such as valet parking and high-speed piloting in subsequent upgrades. The addition of these functions will further enhance the intelligence level and driving convenience of the Changan Qiyuan E07, allowing drivers to enjoy the driving pleasure while also feeling the convenience and peace of mind brought by technology.

The Changan Qiyuan E07 showed outstanding performance and leading technical strength in the driving review activity, which left a deep impression on people in terms of power, handling, comfort and intelligent driving assistance systems. The launch of this model not only marks a solid step for Changan Automobile in the field of electric vehicles, but also indicates that Chinese auto brands are gradually moving to the center of the world stage.

Digital intelligence leads the future and makes a leap towards a better future

As a new achievement of Changan Intelligent Manufacturing, Changan Automotive Digital Intelligence Factory has provided advanced and valuable practical experience for the transformation of China’s automobile manufacturing industry, and is expected to become a new high ground for future automotive intelligent manufacturing.

Thanks to the intelligent variable hard power and high-end intelligent manufacturing empower, the "intelligent variable new car" Changan Qiyuan E07, which has pioneered the industry, has three body variable functions of "SUV, pickup truck, coupe", a solid quality foundation and an integrated super-intelligent experience. It is expected that its starting price will not be less than 300,000 yuan. In the future, Changan Automobile will uphold ingenuity, launch better quality and epoch-making products, and lead China’s automobile industry to climb to the peak with excellent technology.